ACTIVATED CARBON

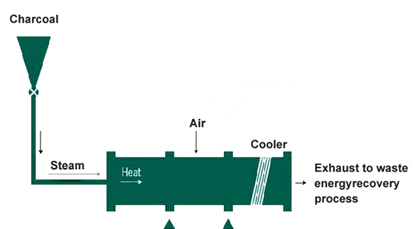

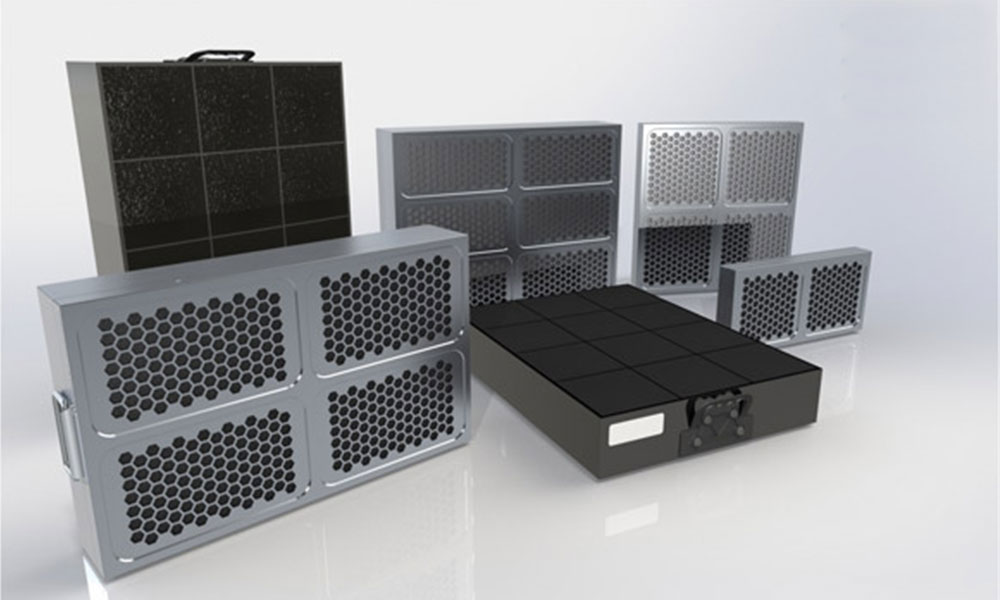

Activated carbon is a porous solid able to coordinate to itself various types of molecules. This interaction can be of merely physical nature (attraction between non-bonded atoms or Van der Waals forces) or physical- chemical origin and its strength can vary depending upon the type of molecule and the type of activated carbon. Activated carbons are usually produced by steam activation process, during which carbon or starting materials containing carbon atoms are partially gasified by reacting with steam or other oxidizing gases. Raw materials such as charcoal, bituminous coal, lignite, coconut charcoal, peat coke or hard wood are used. In addition, chemical activation can also be used to activate raw materials containing cellulose. Saw dust for example is treated with chemicals that have a dehydrating effect at high temperature. Both processes result in porous carbon which consists in an extremely porous structure with highly developed internal surface that can range from 500 up to 1500 square meters per gram of carbon. To cover a wide variety of applications, GALE, starting from raw activated carbons, manufactures more than 40 different activated carbon finished products which are differing in material origin, physical shape (granular, extrudated or powdered), surface area, pore volume distribution, mesh size and other physical properties, in addition to impregnated carbons for special applications. GALE products let answer the most difficult questions in purification field.

- Granular activated carbon

- Extrudated activated carbon

- Powdered activated carbon

- Aktif Karbon Hakkında

AKTİF KARBON NEDİR?

Aktif karbon, farklı molekül yapıları ile birleşebilen, yüzeyi gözenekli katı bir maddedir. Aktif karbonun etkileşimi sadece fiziksel (birbirine bağlı olmayan atomların arasındaki etkileşimle ya da Van der Waals kuvvetlerinin etkileşimi ile) ya da fiziksel-kimyasal yapısı sayesinde olabileceği gibi kuvveti de molekülün tipine ve aktif karbonun tipine bağlı olarak değişebilir. Aktif karbon genellikle buharla aktivasyon prosesi ile üretilir. Bu proseste karbon ya da ya da karbon içeren başlangıç malzemeleri buharla ya da diğer okside edici malzemelerle reaksiyona sokularak gazlandırma işleminden geçirilir. Odun kömürü, taş kömürü, linyit, hindistancevizi bazlı kömür, bataklık kömürü ya da odun bazlı kömür gibi hammaddeler kullanılır.

Ek olarak, hammaddeleri aktifleştirmek için selüloz bazlı hammaddeler de kimyasal aktivasyon işleminde kullanılabilir. Örneğin odun talaşı, yüksek sıcaklıkta dehidrasyon etkisi yapan kimyasallarla işlem görür. Bütün prosesler sonucunda, bir gram karbonda 500-1750 metre kare arasında değişebilen, oldukça gelişmiş yüzey alanına sahip gözenekli aktif karbon elde edilir.

AKTİF KARBONUN YÜZEY ALANI

Aktif karbonun etkinliği yüzey alanına bağlıdır. Etkinlik yüzey alanı arttıkça artar. Aktif karbonun yüzey alanı genellikle 500-2000 metre kare arasında değişir.

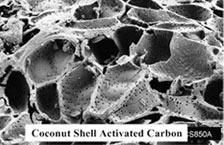

HİNDİSTANCEVİZİ BAZLI AKTİF KARBONUN EŞSİZ ÖZELLİĞİ NEDİR?

Hindistancevizi bazlı aktif karon şimdiye kadar yapılan en etkili aktif karbon olarak kabul edilir.

• Bu aktif karbonun yüzeyi oldukça gözeneklidir ve yüzey alanı oldukça geniştir.

• Gözenekli yapısı hızlı bir adsorbsiyon için uygundur

• Doğada bulunan bir hammaddedir

• Karbon salınımı yoktur

• Sertliği yüksektir

• Safsızlık oldukça düşüktür

ADSORBSİYON NEDİR?

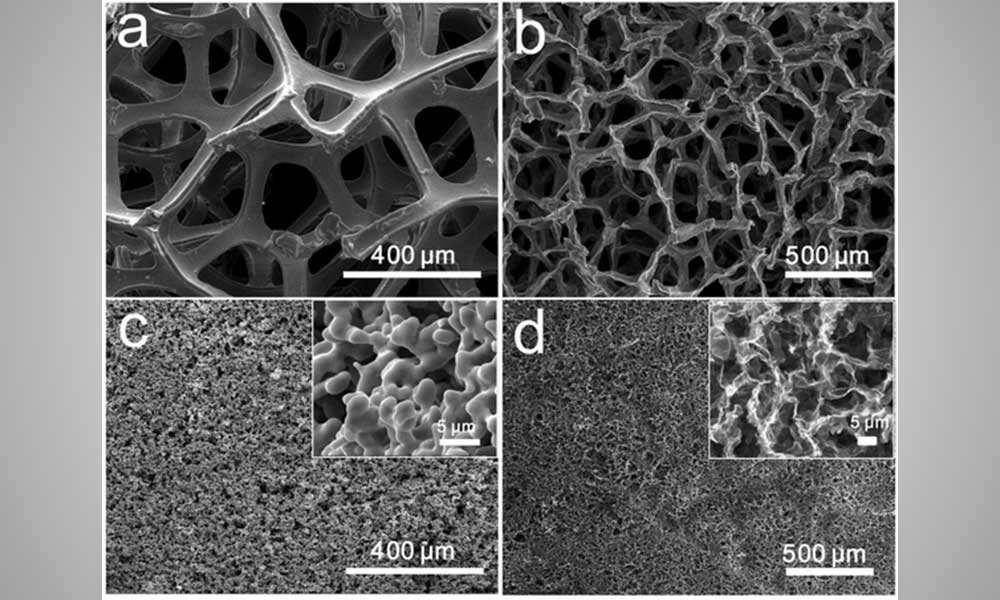

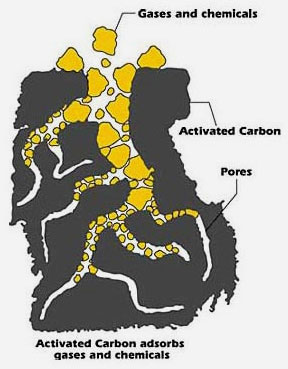

Adsorbsiyon, bir maddenin moleküllerinin aktif karbonun yüzeyine tutunmasıdır. Aktif karbon, adsorbatların iç yüzeye tutunmasını sağlayan yüksek mikro ve makro gözenekler ile karakterize edilir. İki türlü adsorbsiyon vardır.

Adsorbsiyon, bir maddenin moleküllerinin aktif karbonun yüzeyine tutunmasıdır. Aktif karbon, adsorbatların iç yüzeye tutunmasını sağlayan yüksek mikro ve makro gözenekler ile karakterize edilir. İki türlü adsorbsiyon vardır.

Fiziksel adsorbsiyon:

Fiziksel adsorbsiyon, adsorblanacak malzemenin aktif karbonun iç yüzeyine, moleküller arasındaki Van der Waals kuvveti ile tutunması ile olur. Çekim kuvveti, gözenek duvarı ve molekül arasındaki mesafe arttıkça azalır.

Kemisorbsiyon:

Adsorbat molekülleri ile aktif karbonun gözenek duvarına emprenye edilen kimyasal kompleksler arasındaki kuvvetli bağ ile gerçekleşir.

AKTİF KARBON İLE HANGİ MALZEMELER ADSORBLANIR?

Aktif karbon genellikle organik maddeleri adsorblamak amacıyla kullanılır. Aynı zamanda iyodin ve civa gibi bazı ağır molekül ağırlıklarına sahip inorganik maddeler de adsorblanabilir.

Aktif karbonun adsorblama kapasitesi;

a) Molekül ağırlığı arttıkça

b) Fonksiyonel grupların sayısı arttıkça

c) Polarite (kutuplaşma) arttıkça artar.

GRANÜL AKTİF KARBON (GAC) NEDİR?

Granül aktif karbon, düzensiz şekle sahip aktif karbonun öğütülmüş ve elenmiş halidir. Granül aktif karbon yüksek hacimdeki gaz ya da sıvı maddeleri saflaştırmak için kullanılır. Granül aktif karbon, toz aktif karbondan daha sert ve daha uzun ömürlüdür. Birkaç kez reaktive edilerek kullanılabilir.

TOZ AKTİF KARBON (PAC) NEDİR?

Toz aktif karbon genellikle sıvı faz ya da baca gazı uygulamalarında kullanılır. Toz aktif karbonun parçacık dağılımı genellikle 5-150 mikrometre arasında değişir. Kesikli ya da sürekli proseslerde kullanılabilir. Toz aktif karbon, granül aktif karbon gibi reaktive edilemez, tekrar kullanılamaz.

AKTİF KARBONUN ÖZELLİKLERİ

Yüzey Alanı:

Aktif karbonun yüzey alanı 500-2000 m2/g arasında değişir. Yani, yalnızca 3 gram kadar aktif karbon bir futbol sahası büyüklüğünde bir yüzey alanına sahip olabilir. Karbonlu maddelerin yüzey alanı aktivasyon prosesi ile genişletilebilir.

Toplam Gözenek Hacmi (TPV):

TPV, bir aktif karbonun içerisindeki gözeneklerin yarattığı boşluğun toplam hacmini ifade eder. Aktif karbonun etkinliği toplam gözenek hacmi arttıkça artar ve ml/g cinsinden ifade edilir.

Gözenek Hacmi Dağılımı:

Aktif karbonun özelliği gözenek boyutunun dağılımı ile ölçülür. Renksizleştirme uygulamalarında yüksek dağılım oranlı mezapora sahip aktif karbon gerekmektedir.

AKTİF KARBONUN SEÇİM KRİTERLERİ

• Aşınmaya karşı direnç

• Adsorbsiyon kapasitesi

• Optimum akış için parçacık boyutu dağılımı

• Adsorbsiyon ve desorbsiyon oranı

• Ürünün kullanın alanına uygunluğu

• Karbonun yüklenmesi sırasında etkili olabilecek ya da etkileşime girebilecek bazı maddeler

AKTİF KARBONUN PERFORMANSINI ETKİLEYEBİLECEK DURUMLAR

• Farklı hammaddeler

• Hammaddenin durumu ve boyutu

• Aktivasyon besleme oranı

• Aktivasyon sıcaklığı ve basıncı

• Aktivasyon sırasındaki oksijen içeriği

• Son ürün karışımı

Lapis Kimya, pek çok kullanım alanındaki ihtiyacı karşılamak üzere farklı özellik, şekil ve boyutlardaki (granül, extruded ya da toz) ürün seçenekleri ile sektöre hizmet vermektedir.